26 April 2021

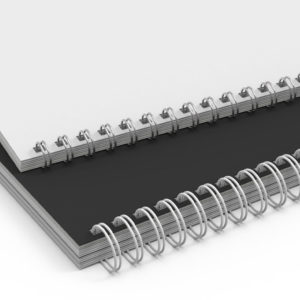

What is the difference between 3:1 and 2:1 pitch binding wires?

If you have never purchased a wire binding machine before you may not be aware of the huge range of wires available for these machines.

While browsing these products can be quite consuming, AfterPrint is here to help to find the best machine for your needs. We have a large selection of binding wires and here we will explain the difference between 2:1 and 3:1 pitches.

2:1 Binding Wires Explained

2:1 binding wires mean that the wires will thread through 2 holes per inch of a document. This is typically 16 loops for A5 and 23 for A4. The looped wire will therefore be spaced further apart than other pitches. The looped wire will therefore be spaced further apart than other pitches and will accept more sheets of paper; making it one of the most popular of the pitches.

3:1 Binding Wires Explained

3:1 binding wires mean that the wires will thread through 3 holes per inch of a document. This typically will be 24 loops for A5 and 34 loops for A4. The looped wire is spaced more closely together than the 2:1 pitch which gives the wires a much tighter look.

It is also worth noting that 3:1 binding wires can accept fewer sheets of paper than 2:1 wires.

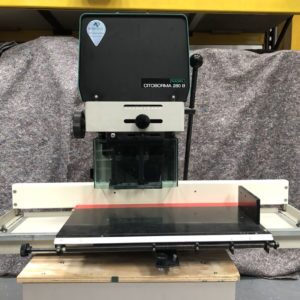

Binding Machines from AfterPrint

Binding machines from AfterPrint are available in a range of styles, each with a different finish and fit for a different purpose.

We have a vast collection of binding machines, meaning we can meet your requirements and give you the best product. AfterPrint recommends doing your research of binding machines before purchasing to make sure you get the right finish for your needs. Another factor to consider is how often the machine will be used and that you are not putting a small-scale machine into a heavy-duty set-up.

If you have any questions about pitch binding wires or binding machines, please do not hesitate to contact us today.